The design of the robot chassis is an important factor in its all performance and capabilities. There are many reasons for the importance of robot chassis design. An important aspect in deciding a robot’s capabilities, dependability, and efficiency is the design of its chassis. A well-designed frame can mean the difference between a robot performing at its peak potential and one that finds it difficult to accomplish its intended objectives. The chassis needs to be built with an even weight distribution without any unnecessary stress spots that might cause mechanical failure. The wheel robot chassis is mostly used to deliver food from one place to another. The wheeled robot is mostly used for indoor work.

Reasons for robot chassis design

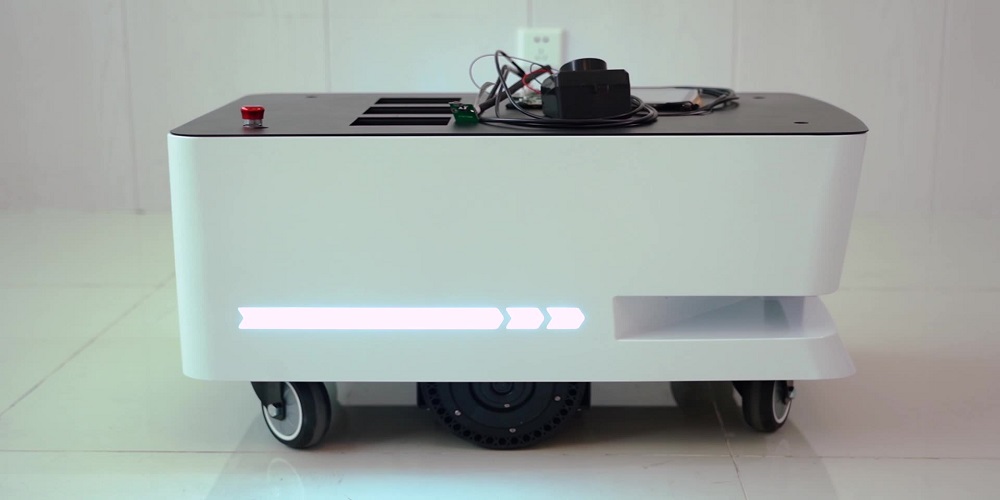

The structural integrity of the robot chassis is designed as the foundation for all other components of the robot. It needs to be structurally sound to guarantee that the robot is steady and secure while operating. The weight and the size of the robot chassis directly influence its mobility and controllability. A well-designed chassis will be small and lightweight, enabling the robot to travel swiftly and easily in various settings. The payload capacity of the robot chassis extra hardware or payload that will be mounted on the robot’s chassis must support its weight. A strong and resistant chassis can support heavier loads, enabling the robot to perform more difficult duties. The compatibility of the robot chassis architecture must work with the individual components and structures that will be mounted on the device.

An attractive frame of robotic chassis makes them easy to manage

Due to the attractive frame, these elements will be simple to install and manage. The customizability of robot adaptation and context adaptation is made possible by flexible chassis designs. The structure can be easily altered by offering a support surface for additional components to satisfy various needs. The chassis layout is important when deciding a robot’s capabilities, dependability, and efficiency.

The applications of robotics chassis

Robotic chassis are used in various situations and industries requiring versatility and movement. In industrial automation, Robotics platforms are frequently used in manufacturing facilities to move materials, carry out menial duties, and even assemble goods. In research and development settings, robotics chassis are commonly used to test novel methods and operational life. Developers can modify the chassis and attach sensors and other hardware to create custom robots for particular tasks. In healthcare environments, robotic systems are used for patient monitoring and transfer. They may be made to move through medical halls and converse with hospital devices.

How security and military use robotic chassis

Security and military uses include robotic chassis for operations like explosive ordnance disposal, observation, and monitoring. They may have monitors, cameras, and other devices to perform these functions in dangerous or remote locations. To educate students about robotics and programming, robotics chassis are frequently used in classroom settings. By changing and programming a chassis to carry out particular functions, students can learn about the construction and operation of robots. Robotic chassis have a wide range of applications in various industries and settings where mobility, flexibility, and adaptability are essential. Their design can be customized to meet specific requirements, making them versatile and useful for various tasks.